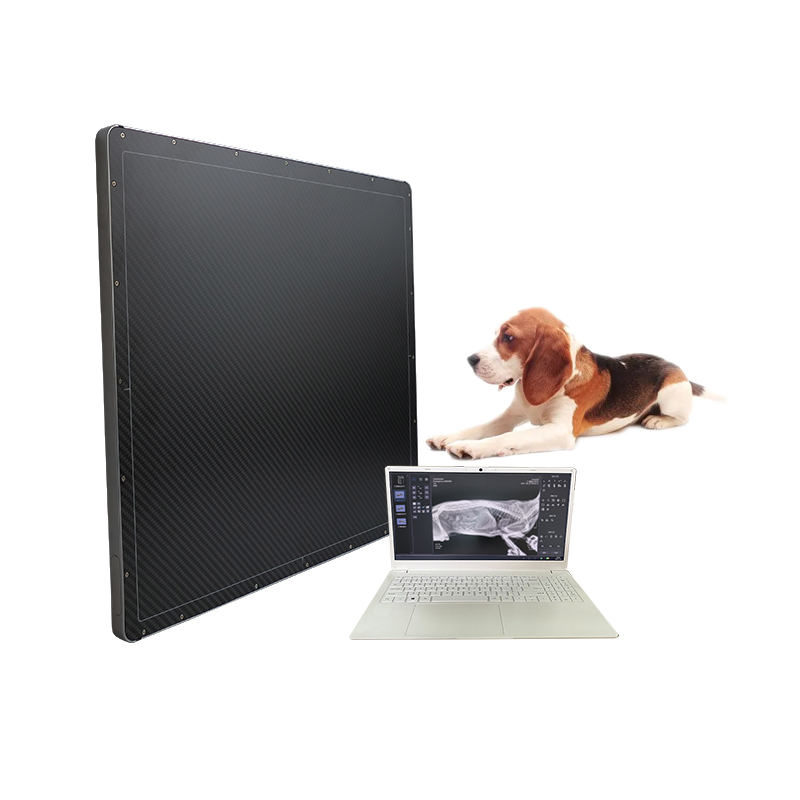

Many people often ask how long the service life of a DR flat panel detector is?In the world of medical imaging, technology plays a crucial role in capturing high-quality images for accurate diagnoses. One such technological advancement is the use of flat panel detectors (FPDs) in digital radiography (DR). FPDs are thin, lightweight devices that have replaced the traditional film-based X-ray systems. These detectors consist of a scintillator layer, which converts X-ray energy into visible light, and an active matrix array of photodiodes that convert the light into an electrical signal.

When investing in a DR flat panel detector, one of the key factors to consider is its service life. The service life of a detector refers to the period during which it can continuously perform optimally without significant degradation in image quality or increased risk of failure.

Several factors can influence the service life of a DR flat panel detector. the manufacturing quality and design play a vital role. High-quality detectors are built to withstand the rigors of daily use in a medical environment. They are constructed with durable materials and undergo thorough testing to ensure reliability and longevity.

proper handling and maintenance practices can greatly extend the service life of a DR flat panel detector. Ensuring that the detector is handled with care during installation, use, and transportation can prevent mechanical damage that may lead to premature failure. Regular cleaning and calibration also help maintain optimal performance and minimize any potential degradation over time.

environmental conditions can impact the service life of a DR flat panel detector. Exposure to extreme temperatures, humidity, or corrosive substances can affect the functionality of the detector. It is essential to store and operate the detector within the recommended temperature and humidity ranges provided by the manufacturer. Proper shielding from harsh environmental factors can help prolong the detector’s lifespan.

The number of exposures performed by a detector also influences its service life. Manufacturers generally specify the maximum number of exposures a detector can handle before its performance starts to deteriorate. It is crucial to consider this specification and choose a detector that aligns with the anticipated workload. Regularly monitoring the detector’s usage and planning for timely replacements can prevent unexpected failures and interruptions in the imaging workflow.

In addition to these factors, technological advancements are continuously improving the service life of DR flat panel detectors. With each iteration, manufacturers refine their designs, incorporate more robust materials, and enhance performance capabilities. Keeping up with the latest advancements and choosing detectors from reputable manufacturers can ensure a longer service life.

When assessing the service life of a DR flat panel detector, it is important to consider the overall cost-effectiveness. Detectors with longer service lives may have a higher upfront cost but can provide significant savings in the long run by minimizing the need for frequent replacements and reducing downtime due to failures.

the service life of a DR flat panel detector is a crucial aspect to consider when investing in medical imaging technology. Manufacturing quality, proper handling and maintenance, environmental conditions, exposure volume, and technological advancements all contribute to the overall service life of a detector. By understanding and addressing these factors, healthcare facilities can ensure optimal diagnostic imaging outcomes while maximizing the lifespan of their DR flat panel detectors.

Post time: Nov-06-2023