The meaning of industrial X-ray machine inspection: a non-destructive testing method that uses the characteristics of X-ray penetration and attenuation in the material to find defects in it. X-rays can inspect the internal defects of metal and non-metal materials and their products, such as volumetric defects such as pores, slag inclusions, and lack of penetration in welds. Using the method of X-ray fluorophotography, the internal defects of the parts processed from the material and the welding are displayed from the X-ray film to evaluate the quality of the product, so as to judge the quality of the product, improve the production process and improve the product. quality, and increase the market competitiveness of products.

Application of industrial X-ray machine inspection: widely used in auto parts, electronic parts, castings, chemicals, containers, medicine, semiconductors, lithium batteries, semiconductor IGBTs, PCB circuit boards, diodes, LED light bars and other products.

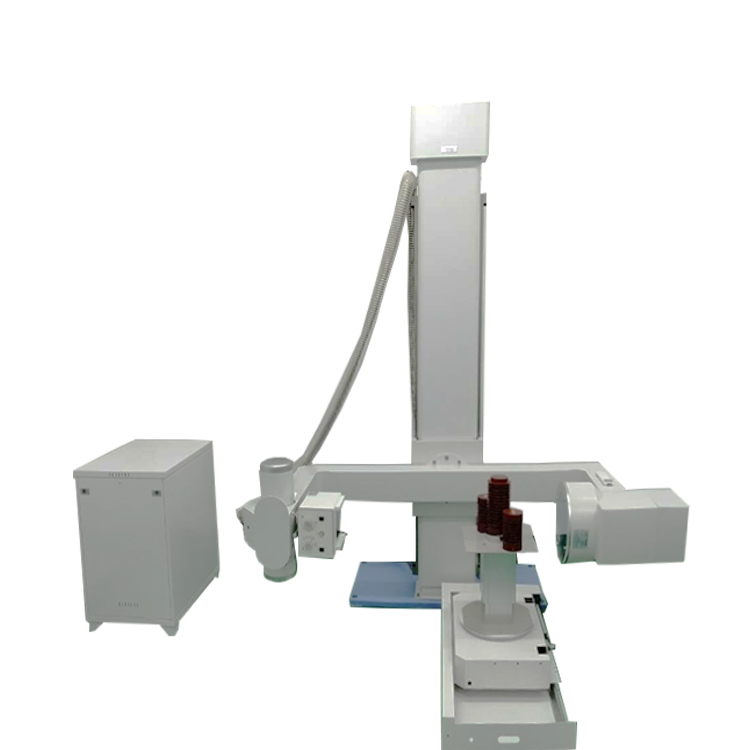

We Weifang Newheek Electronic Technology Co., Ltd. is a professional manufacturer of X-ray machines and accessories. Welcome to consult, telephone (whatsapp): +8617616362243.

Post time: Oct-12-2022